- Home

- Uncategorized

- Fully Automatic Roll Fed Twisted Handle Paper Bag Machine

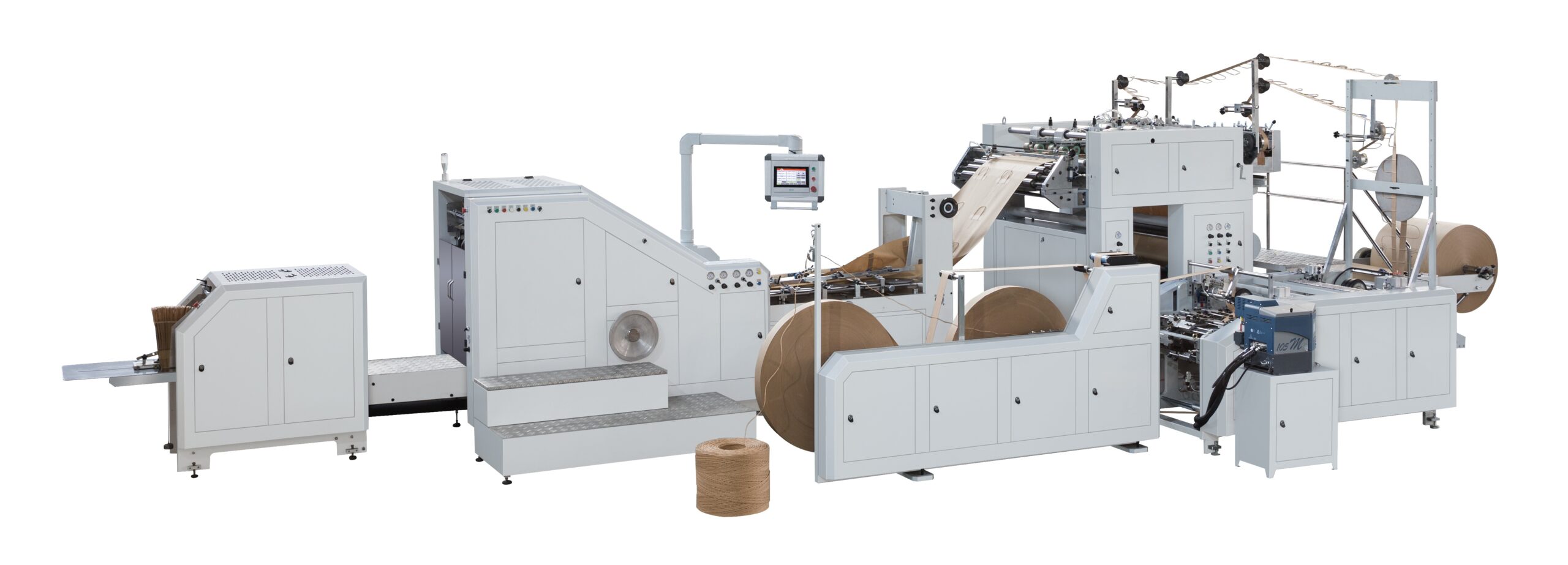

Fully Automatic Roll Fed Twisted Handle Paper Bag Machine

This machine is designed to manufacture square bottom paper bags with twisted handle from paper roll, paper patch roll and paper rope. YASKAWA PLC Control system imported from Japan and adjustable dual-moulds structure, ensure that the machine can perform quickly and stably, as well as reduce adjusting time for different bag sizes. Front bags collection platform and counting function, improve packing efficiency of paper bags packing. By implementing steps including handle making. handle application, tube forming, tube cutting, and bottom forming with a fully automatic process. That is especially suitable for foodstuff, clothing and luxury branding products.

Category: Uncategorized

- Description

- Reviews (0)

Description

Description

| (W) Bag Width | 140-330 mm no handle 200-330 with handle | |

| (H) Bottom Size | 70-180 mm | |

| (C) Cutting Length | 380-750 mm No handle | 380-650 mm With handle |

| (L) Bag Length | L=C-(H÷2+15~25) | |

| Max. Speed | 120 pcs/min | |

| Paper Roll Width | 400-1050 mm | |

| Max. reel weight | 600 Kg | |

| Max.Roll Diametr | 1200 mm | |

| Reel inner diameter | 76 mm | |

| Paper specification | 60-170 gsm | |

| Handle Rope Height | 100 mm | |

| Handle Rope Diameter | 4-6 mm | |

| Paper rope spacing | 76.2mm | |

| Handle Patch Length | 152.4mm | |

| Handle Patch Width | 35-50 mm | |

| Paper Patch Roll Diameter | 1200 mm | |

| Paper Patch Roll Width | 70-100 mm | |

| Paper Patch Thickness | 100-150 gsm | |

| Web edge control system | Double photoelectric automatic correction control system | |

| Web tension control system | automatic constant tension control system | |

| Air pressure | ≥0.12 m³, 0.6~1.2Mpa | |

| Driven motor | Seven servo motors | |

| Electric | 380V,50 Hz,3相 380V, 50Hz, 3 phase | |

| Power | 27 KW | |

| Weight | 14800 Kg | |

| Overall dimension(L×W×H) | 13000×5700×2500 mm | |

Reviews (0)

Be the first to review “Fully Automatic Roll Fed Twisted Handle Paper Bag Machine” Cancel reply

Reviews

There are no reviews yet.