No. | Term name description | Technical Parameters |

适用原料Applicable raw materials | PP, PS, PET, PVC, OPS, degradable materials, PLA. etc. | |

成型方式Forming method | 正负压成型Positive and negative pressure forming | |

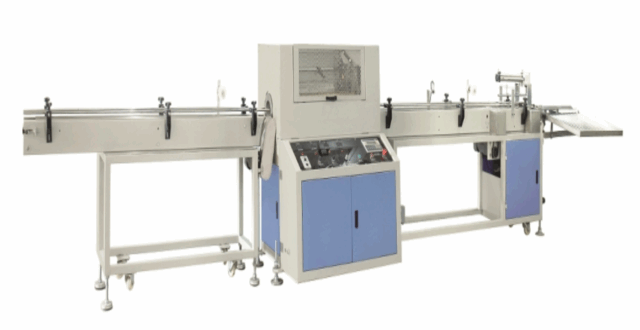

最大成型面积Maximum forming mold area | 780*600mm | |

最小成型面积Minimum molding die area | 420×300mm | |

最大片材宽度Maximum sheet width | 820mm | |

适用片材厚度Applicable sheet thickness | 0.15-2.0mm | |

最大冲切面积Maximum punching area | 780×600mm | |

裁切刀线Cutting knife line | 10M knife line | |

成型模具最大开合行程Maximum opening and closing stroke of forming mold | 165mm | |

成型产品高度Molded product height | 150mm | |

堆叠机构Stacking mechanism | push-down stack 下推堆叠 | |

整机额定功率Rated power of whole machine | 120kw | |

消耗功率Power consumption | 25-50kw | |

电源接入Power access | 380V/50HZ (three-phase five-wire) | |

整机重量 Total Weight | 17,000kg | |

外观尺寸physical dimension | L13m×W2.4m×H2.6m | |

最大片材料卷径Maximum sheet material roll diameter | 1100mm (within 500KG) | |

工作效率Work efficiency | 30 molds/minute (材料厚度而定depending on material thickness) | |

冷却方式cooling method | 模具通循环水冷却The mold is cooled by circulating water |

- Description

- Reviews (0)

Description

No. | Name | Brand |

控制系统Control System | 控制系统Control System | 德国倍福Beckhoff System |

可编程控制器Programmable Controller (PLC) | 德国倍福Beckhoff System | |

触摸显示器Touch display | 15寸彩色触控显示器15 inch color touch monitor | |

拉片伺服系 统 Pull tab servo system | 拉片伺服系统Pull tab servo system | TAIDA5.5kw |

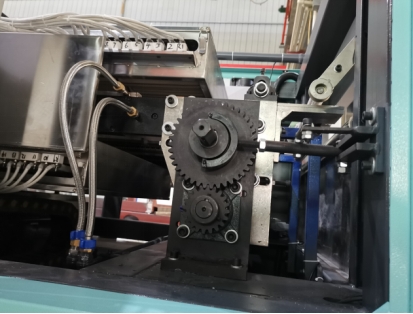

拉片减速箱Pull tab gearbox | 高精度行星减速器High precision planetary reducer | |

链条导轨Chain guide | 航空铝合金表面硬氧处理 Aerospace aluminum alloy surface hard oxygen treatment | |

拉片链条Pull tab chain | 双排导向链条 double-row guide chain | |

导轨(大梁)冷却系统Rail (beam) cooling system | 大梁整体通水冷却(循环水)The whole beam is cooled by water (circulating water) | |

导轨调节Rail adjustment | 导轨电动调节,并可以单向调节 The guide rail is electrically adjusted and can be adjusted in one direction | |

驱动系 统 Drive System | 循环次数Cycles | 30 times/minute |

成型伺服系统Forming Servo System | TAIDA5.5kw+5.5kw | |

选配冲孔、裁切伺服系统Punching and cutting servo system | TAIDA5.5kw +7.kw | |

堆叠伺服系统Stack Servo System | TAIDA2.0kw | |

Station structure | Cam structure | |

加热系统 Heating system | 智能温控系统Intelligent temperature control system | 庄谷(hero)一控一电脑数字控温 日本山武测温模块 陶瓷发热砖(瑞典KANTHAL进口发热丝) Zhuanggu (hero) one control one computer digital temperature control Japan Yamatake temperature measurement module Ceramic heating brick (Sweden KANTHAL imported heating wire) 加热炉长度是成型长度的3倍、上下炉加热,下炉有防护钢网。耐高温线,具有电流过载保护。 The length of the heating furnace is 3 times of the forming length, the upper and lower furnaces are heated, and the lower furnace has a protective steel mesh. High temperature resistant wire, with current overload protection. |

远红外陶瓷发热器Far infrared ceramic heater | ||

热炉(不锈钢热炉) Hot stove (stainless steel hot stove) | ||

冷却系 统cooling system | 冷却系统cooling system | |

冷却方式cooling method | 模具通循环水冷却(进出水口各6个)The mold is cooled by circulating water (6 water inlets and outlets) | |

成型工位 Forming station | 成型工位Forming station | 成型上模台高度可调50mm The height of the upper mold table can be adjusted by 50mm |

Positive air pressure valve | 日本SMC超高速响应流体阀 Japan SMC ultra-high-speed response fluid valve | |

Bottom wind | 底风采用大气量阀 Bottom air adopts atmospheric volume valve | |

安全装置 safely device | 配有安全挂钩,方便操作 | |

真空泵Vacuum pump | 德国伟力100M3/H (配大流量真空阀)Germany Rietschle 100M3/H (with large flow vacuum valve) | |

裁切工位Cutting station Cutting part | 裁切部分Cutting part | 伺服直接冲裁;成型上模台高度可调50mm Servo direct blanking; the height of the forming upper die table can be adjusted by 50mm |

安全装置safely device | 配有安全挂钩,方便操作Equipped with safety hooks for easy operation | |

堆叠系统Stacking system | 自动点数,自动堆叠功能 Automatic points, automatic stacking function | |

收卷系统Winding system | 变频全自动收卷功能,可调力矩功能Frequency conversion automatic winding function, adjustable torque function | |

安全系统Security system |

3.漏电、过载安全开关 1. Equipped with safety grating devices on the left and right sides 2. Part of the machine is equipped with an emergency stop device 3. Leakage, overload safety switch | |

润滑系统Lubrication system | ||

上料系统Feeding system | ||

电器Electrical appliances | 导轨配备针阀式油杯润滑系统 The guide rail is equipped with a needle valve type oil cup lubrication system | |

双料杆自动机械上料卷装置,卷径1100mm,可承受500KG Double material bar automatic mechanical feeding roll device, roll diameter 1100mm, can bear 500KG | ||

交流接触器日本富士 AC contactor Japan Fuji | ||

接近开关日本欧姆龙 Proximity switch Japan Omron | ||

开关电源 台湾明纬 Switching power supply MEAN WELL | ||

Reviews

There are no reviews yet.