- Home

- Uncategorized

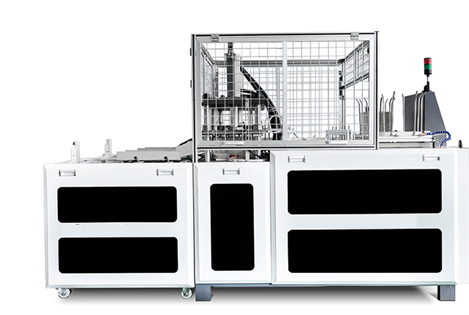

- Automatic High-Performmance Pressure And Vaccum Thermoforming Machine

Automatic High-Performmance Pressure And Vaccum Thermoforming Machine

特点 Feature:

全自动伺服正负压成型冲切一体机,省人力、省电1/3。吸塑模具第二次生产时,报废率可为零,可以代替以往普通吸塑机不能生产的产品(水纹不均匀,空隙小等高难度)而要使用效率低、浪费电的单头吸塑机,现在我们以用新一代的全自动正负压一体机解决高难度的吸塑产品,提高产品的质量、效率,使产品更完美。

Full-automatic high speed forming machine can save 1/3 manpower and power . During the second production, the waste rate even could be zero. It could replace the single head plastic forming machine which with low efficiency and waste of electricity to produce the products that cannot be produced by ordinary plastic forming machines in the past (uneven water lines, small gap). Now we use the new generation automatic positive and negative pressure integrated machine to produce difficult plastic forming products and improve the quality and efficiency of the products and finally make the products more perfect.

用途 Application:

适用于 PS、PP、PVC、PET、HPS、等塑料片材的成型,加工高透明、圆型、方型、不规则等产品,生产各种盒、碟、托盘、碗、盖、工业包装、食品包装、化装品包装以及其它包装类等塑料制品。

It is suitable for the forming of PS, PP, PVC, PET, HPS, and other plastic sheets. Highly transparent, round, square, irregular and other products could be processed on this machine. And it could produce various boxes, plates, trays, bowls, covers, industrial packaging, food packaging, cosmetic packaging and other packaging and other plastic products.

设备工艺流程 Machine production process flow:

供给片材→输送片材→加热→成型冷却→裁切→分解堆叠→废料自卷系统

注:共三工位生产线,操作方案:手动/自动一体相互切换作用,手动便于取样、控制参数设置。

Supply sheet →sheet feeding → heating → forming and cooling → cutting → stacking → waste sheet edge winding system

Note: there are three station production lines in total. Operation scheme: manual / automatic integration and mutual switching. Manual is convenient for sampling and control parameter setting.

- Description

- Reviews (0)

Description

- 产品介绍/ Introduction

1.1控制系统 Control system

台达人机界面,10.1寸彩色触摸屏。专业操作系统,包含自动操作、手动操作、功能设置、机械动画、故障显示、设备文档、安全指引等界面,并有生产参数记忆功能,整套系统运行简易和稳定。

Taiwan Delta human-machine interface, 10.1-inch color touch screen. The professional operating system includes interfaces such as automatic operation, manual operation, function setting, mechanical animation, fault display, equipment documentation, safety guidance, etc. It also has production parameter memory function, making the entire system operate easily and stably.

1.2 上料区 Unwinding unit

上料采用气缸升降,托重可达 500 公斤。待料送片用胶辊带动,备有二支料杆用于更换片材母卷,上片材区设有 2 只喷头为喷硅油装置,方便脱模。

Cylinder lift is used for unwinding material, and the supporting weight could reach 500 kg. The sheet feeding is driven by rubber rollers. Two metal rods are provided for changing sheets rolls. There are two nozzles specially for spraying silicone oil on the sheet surface to removing sheets from mold easily.

1.3 电热区 Heating unit

1850mm长电炉采用耐热不锈钢制作,上下电炉加热。电炉采用“JINNAN”650W发热瓦,进口耐火线,高频瓷接头。上下电加热炉总共有180 块 650w 发热瓦,最大功率 100KW,采用奥仪12 路智能模块集成温控系统,一对一控制温度,集成式故障诊断系统实现故障检测、定位并报告故障信息,显著提升生产效率并将停机时间降至最低。数据储存可达1000 组,方便数据管理。电炉气缸驱动以实现电炉自动进出功能(适用PET材料)。此外,电炉在停电或检修电炉时可退出机外,安全方便。

The electric furnace with length of 1850mm is made of heat-resistant stainless steel and there are both upper and lower furnace. Totally 180 pcs “JINNAN” 650W heating tile, imported refractory wire, high-frequency porcelain joint and Aoyi 12-way intelligent module integrated temperature control system are used to make as this machine’s upper heating unit. Its maximum power is 100KW and it has one-to-one temperature control function and integrated fault diagnosis function to realize fault detection, locate and report all pending faults, which could significantly improve production efficiency and minimize machine stop time. Besides, data storage could reach 1000 groups and it is easy to do data management. What’s more, there are electric furnace reciprocating function which could heat the PET sheet in a short time and make the PET material easy to form effectively. And the electric furnace’s exiting function is safe and convenient when there is power failure or machine maintenance

1.4 成型区 Forming unit:

成型片材长度340~650mm 内不限,成型片材宽度 380~760mm,成型高度最大110 mm,成型上下模台采用4.5KW台湾伺服电机,可分段控制速度,准确度控制在0.7C。

The length of the forming sheet is not limited within 340~650mm, the width of the forming sheet is 380~760mm, and the maximum forming height is 110 mm. The upper and lower forming mold tables adopt 4.5KW Taiwan servo motors, which could control the speed in sections and the accuracy is 0.007mm.

1.5 裁断区 Cutting unit:

裁断上下模台分别采用7.5KW和5.5KW台湾伺服电机,准确度高和压力大。

备注:预留热刀接线,PET片材厚度超过1mm需要用加热刀

The upper and lower cutting mold tables are equipped with 7.5KW and 5.5KW Taiwan servo motors, which have high accuracy and strong pressure.

Note: Reserved hot knife connecting cable, PET sheet thickness exceeding 1mm requires to use hot knife for better cutting effect

1.6链轨传动Chain drive:

链轨宽窄由电机调节,链轨主体为铝型材硬氧化带扣槽设计,使用寿命长。拉片链条采用硅钢片制作,驱动采用 4.5kw 伺服电机,拉片快速而准确。最大使用片材厚度 PP、PS 可达 2.0 mm, PVC、APET、ABS 可达 1.5 mm。

The width of the chain rail is adjusted by the motor. The main body of the chain rail is designed with an aluminum profile hard anodized buckle groove, which has a long service life. The pull-tab chain is made of silicon steel sheet which is driven by 4.5kw servo motor quickly and accurately. Maximum used sheet thickness PP, PS up to 2.0 mm, PVC, APET, ABS up to 1.5 mm

1.7 机械臂用于堆叠产品 Robotic arm to stack products

机器采用智能机械臂系统帮助堆叠产品,确保产品在切割后能够快速从机器中取出。产品按照操作系统上安装的数量排列整齐,帮助客户节省计数时间。

The machine uses a smart robot arm system to help stack products, ensuring that after being cut, the product will be quickly removed from the machine. Products are neatly arranged, according to the quantity installed on the operating system, helping customers save time counting.

1.8 冷却系统 Cooling system:

10HP冷水机+强力高速运水的独立管道

10HP chiller + independent big water pipeline

1.9真空系统 Vacuum system:

真空泵,抽气速度为每小时 160m3。超大的真空泵及真空缸容量设计,满足瞬间强大的真空释放需求,得以让产品成型更快速,质量更高。

Vacuum pump, pumping speed is 160 m3 per hour. The super-large vacuum pump and vacuum cylinder capacity design could meet the demand for instant and powerful vacuum release, so that the product could be formed faster and with higher quality.

1.10 电柜Electrical Cabinet

电柜系统采用台湾台达、日本CKD、日本富士等知名品牌的现代化电气设备…

The electrical cabinet system uses modern electrical equipment from famous brands such as delta – Taiwan, CKD Japan, Fuji Japan…

1.11 废料收边Scrap edge collection

自动垃圾收集系统,通过开关调节开关,有助于提高机器的工作效率,确保垃圾收集整齐。

The automatic waste collection system, adjusted on and off with a switch, helps increase the machine’s working efficiency, ensuring the waste is collected neatly.

Ⅱ. 参数配置表 Technical data:

| 01 | 吸塑成型方式 Forming Method | 正负压成型 Positive and negative pressure forming |

| 02 | 成型长度 Forming length 成型宽度 Forming width | 340mm-650mm 380mm-750mm |

| 03 | 成型最大深度 Max forming depth | ≦110mm |

| 04 | 拉片 Plastic sheet feeding | 4.5kw TAIWAN Delta servo motor |

| 05 | 上模成型工位Upper die forming station 上模具上下牵引电机Upper mold up and down traction motor 下模成型工位Lower die forming station | 4.5kw TAIWAN Delta servo motor 3.0kw TAIWAN Delta servo motor 4.5kw TAIWAN Delta servo motor |

| 06 | 上冲切工位Upper punching station 下冲切工位Lower punching station | 7.5kw TAIWAN Delta servo motor 5.5kw TAIWAN Delta servo motor |

| 07 | 产品堆叠Product stacking station | 2.0kw+1.5kw TAIWAN Delta servo motor |

| 08 | 总功率 Total power | 150KW(Max), 380V 50HZ |

| 09 | 机械尺寸 Machine dimension | L9500mmxW2200mmxH3200mm |

| 10 | 机械重量 Machine weight | About 11.5T |

| 11 | 操作系统 Operation system | 10.1inch touch screen(Delta, Taiwan) |

| 12 | 电磁阀 Solenoid valve | CKD Japan/ SHAKO Taiwan |

| 13 | 发热砖 Heating brick | German type heating brick “Jinnan”, furnace with length of 1850mm |

| 14 | 设备主要电器配置 Main electrical equipment configuration | Taiwan Delta, Japan Fuji |

| 15 | 冷却方式 Cooling Method | Water cooling machine, 10HP |

| 16 | 负压产生方式 Vacuum Method | 160m3 Vacuum pump(Shanghai Zhongde) |

| 17 | 繼電器 Relay | Schneider, France |

| 18 | 空氣開關、接觸器、行程開關 Air switch, contactor, travel switch | Fuji, Japan |

Reviews

There are no reviews yet.