- Home

- Uncategorized

- Cornstarch Biodegradable Plastic Pellet Making Machine

Cornstarch Biodegradable Plastic Pellet Making Machine

公用工程要求: Utility Requirements | |

| 电源要求 Power Supply | 380V/3P/50Hz |

| 总功率 Total Power | 360Kw |

| 设备尺寸(长 × 宽 × 高)Dimension of the Equipment (Length x Width x Height) | 40000mm*5000mm*8500mm |

| 总重 量 Weight | 9 Tons |

| 适用材料 Applicable material | PP, 加玉米淀粉及填充材料 PP, Cornstarch and filling material |

| 产量 Output Capacity | 500-600㎏/小时,具体产量取决于原材料熔体流动速率、比重、配方和生产工艺 500-600Kg/hour, the specific yield depends on the melt flow rate, specific gravity, formulation and production process of raw materials |

- Description

- Reviews (0)

Description

- 物料供料设备

Material Feeding Equipment

| |

| 电源要求 Power Supply | 380V/3P/50Hz |

| 总功率 Total Power | 105Kw |

| 设备尺寸(长 × 宽 × 高)Dimension of the Equipment (Length x Width x Height) | 5000mm*5000mm*8500mm

|

| 总重 量 Weight | 3.5Ton |

| 设备挤出产量 Capacity | 600-800Kg/h |

| 1.1. 料仓+投料站 Bin + feeding station | |

| |

| 外形尺寸 Outline dimension | 800/1200/1800mm |

| 材质 Material quality | SUS304 |

| 厚度 Thickness | 2mm |

| 除尘方式 Dusting method | VF-4脉冲式除尘 VF-4 pulse dust removal |

| 除尘的主要特点:为不锈钢组合式结构,拆装清洗维修及其方便。 外形美观,造型独特,密封性能好。 采用透气性能好,分离效率高的过滤材料分离物料及过滤空气,有效地防止微细物料粉末进入气泵及污染周围环境。 反吹储气罐及反吹电磁阀能按设定周期自动反吹清洗过滤,反吹能力强,反吹效率高。 Main features of dust removal: It is a stainless-steel combination structure, which is easy to disassemble, clean and maintain. The appearance is beautiful, the shape is unique, and the sealing performance is good. The material with good air permeability and high separation efficiency is used to separate materials and filter air, effectively preventing fine material powder from entering the air pump and polluting the surrounding environment. The reverse blowing storage tank and the reverse blowing solenoid valve can automatically blow clean the filter according to the set cycle, with strong reverse blowing capacity and high reverse blowing efficiency. | |

| 风机电动机功率 Fan motor power | 7.5KW |

| 电源 source | 50HZ/380V 三相四线制 50HZ/380V three-phase four-wire system |

| 反吹气源压力 Reverse blow pressure source | 0.4MPa |

| 设备外形尺寸 Contour size of the unit | 500×500×1500mm |

| 设备重量 Weight of equipment | 100kg |

| 脉冲控制 Impulse control | 宁波裕达集团 Ningbo Yuda Group |

| 输送管道 running piping | |

| 上口接真空吸料机 The upper opening is connected to the vacuum feeder | |

| 下口接投料站 The lower outlet connects to the feeding station | |

| 直径 Diameter | 100mm(无缝管) 100mm (seamless tube) |

| 材质 Material quality | SUS304 SUS304 |

| 厚度 Thickness | 2mm |

| 长度 Length | 约为5米(包含2个90°弯头) About 5 meters (including 290° elbows) |

| 1.2. 真空粉末吸料机 Vacuum powder feeder | |

| |

| 气泵电机功率 Air pump motor power | 7.5KW |

| 上料量 Feed rate | 约1000kg/h About 1000kg/h |

| 输送料管直径 Diameter of feed pipe | 100mm |

| 吸气管直径 Inhalation tube diameter | 100mm |

| 输送高度 delivery head | 0-10米 0-10 meters |

| 下料阀 Feed valve | 有脉冲反吹装置 Pulse blow-off device |

| 滤芯 filter element | 7个高效滤芯 7 high efficiency filter elements |

| 脉冲阀数量 Number of pulse valves | 3只 Three |

| 滤袋数量 Number of filter bags | 7只 Seven |

| 接触器 contactor | 施耐德 Schneider |

| 继电器 electric relay | 施耐德 Schneider |

| 投料站 Feed station | 2mm不锈钢制作 Made of 2mm stainless steel |

| 不锈钢料斗容积 Stainless steel hopper volume | 1500L |

| 表面抛光处理 Surface polishing treatment | |

| PLC及触摸屏 PLC and touch screen | 信捷 Xinjie |

| 桶身直径 Bottle diameter | Φ977 |

| 桶身高度 Bottle height | Φ2350 |

| 搅拌电机 Motor for stirring | 2.2KW |

| 除尘形式 Dust removal form | VF-4脉冲式除尘 VF-4 pulse dust removal |

| 1.3. 高低机 Elevating mechanism | |

| |

| 高混机 High mixer | 1套 1 set |

| 总容积(L) Bulk volume (L) | 500 |

| 有效容积(L) Available capacity (L) | 350 |

| 一次投料量(Kg) One feed rate (Kg) | ≤200(具体视物料密度) ≤200 (depending on material density) |

| 混合时间(min) Mixing time (min) | 12-15 |

| 产量(Kg/h) Output (Kg/h) | 200 |

| 主轴转速(r/min) Spindle speed (r/min) | 800 |

| 加热方式 Heating method | 电加热 electrical heating |

| 物料温度(OC) Material temperature (OC) | ≤120 |

| 启动方式 Starting mode | 加软启动 Add soft start |

| 控温方式 Temperature control method | 自动 voluntarily |

| 排料方式 Discharge mode | 气动 pneumatic |

| 电动机功率(Kw) Motor power (Kw) | 90 |

| 低混 Low mixing | 1套 1 set |

| 容量 Capacity | 1000L |

| 电机功率 Motor power | 11KW |

| 1.4. 钢平台 Steel platform | |

| |

| 材质 Material | Q235,表面防锈漆喷漆处理 Q235, surface anti-rust paint spraying treatment |

| 尺寸 Size: | 2.5M*3M |

| 可我方提供图纸买方制作 However, we will provide drawings for the buyer to make | |

| 每平方承重 It can bear | 500KG per square meter |

| 1.5. 双螺杆计量喂料机 Double screw metering feeder | |

| |

| 电机 Motor | 1.5KW |

| 技术规格 Specification | 喂料体带卧式搅拌,英威腾变频调速 The feeding body is equipped with horizontal stirring, and the frequency converter speed control is implemented by INVTEX |

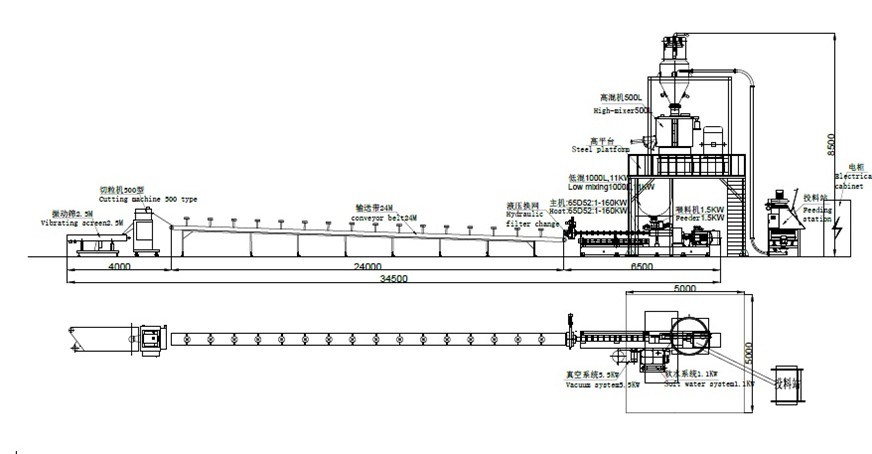

- 玉米淀粉生物可降解塑料造粒机

Cornstarch Biodegradable Plastic Pellet Making Machine

| |||||

| 电源要求 Power Supply | 380V/3P/50Hz | ||||

| 适用材料 Applicable material | PP, 加玉米淀粉及填充材料 PP, Cornstarch and filling material | ||||

| 总功率 Total Power | 270Kw | ||||

| 设备尺寸(长 × 宽 × 高)Dimension of the Equipment (Length x Width x Height) | 34500mm*1000mm*1300mm | ||||

| 总重 量 Weight | 5.5Ton | ||||

| 设备挤出产量 Capacity | 500-600Kg/h | ||||

| 2.1. 双螺杆挤出机 Twin screw extruder | |||||

| |||||

| 电源要求 Power Supply | 380V/3P/50Hz | ||||

| 适用材料 Applicable material | PP, 加玉米淀粉及填充材料 PP, Cornstarch and filling material | ||||

| 功率 Power | 250Kw | ||||

| 设备尺寸(长 × 宽 × 高)Dimension of the Equipment (Length x Width x Height) | 6500mm*1000mm*1300mm | ||||

| 总重 量 Weight | 4.5Ton | ||||

| 设备挤出产量 Capacity | 500-600kg/h | ||||

| D型高扭齿轮减速箱 D type high torsion gear reducer | 1台 1 Unit | ||||

| |||||

| 技术规格 Specification | 双螺杆计量进料器 减速、扭矩分配及两根输出轴径向轴承均使用NSK轴承。 NSK bearings are used for speed reduction, torque distribution and radial bearings of two output shafts in the twin screw metering feeder. | ||||

| 减速比 Reduction gear ratio | 2.5:1 | ||||

| 输出轴转速 Output shaft speed | MAX500RPM | ||||

| 输入轴转速 Input shaft speed | MAX 1500RPM | ||||

| 输出扭矩 Torque output | ≥2﹡1200Nm | ||||

| 润滑油冷却设备 Oil cooling Equipment | 1套 1 set | ||||

| |||||

| 油泵电机 Oil pump motor | 1.1KW | ||||

| 润滑油型号 Type of lubricating oil | 上海牌6402中负荷齿轮油,型号85W/90GL-4 Shanghai Brand 6402 medium load gear oil, model 85W/90GL-4 | ||||

| 冷凝器型号 Condenser model | SL-506 | ||||

| 润滑油泵型号 Lubricating oil pump model | NB-B9 | ||||

| 主机电机 Main motor | 1台 1 unit | ||||

| |||||

| 主机电机 Main motor | 西门子贝得电机交流电机160KW,电机尾部带独立风扇 Siemens Betta motor AC motor 160KW, motor tail with independent fan | ||||

| 电机转速 Motor speed | 1500rpm | ||||

| 电压 Voltage | 380V,50HZ | ||||

| 积木式螺杆 Building block screw | 1套 1 set | ||||

| |||||

| 螺杆直径 Screw diameter | 62.4mm | ||||

| 长径比L/D Draw ratio L/D | 52:1 | ||||

| 芯轴 Dabber | 40CrNiMoA材质,螺纹元件与芯轴为渐开线联结,强度高,承载负荷大,拆装组合方便 40CrNiMoA material, the threaded element and the core shaft are connected by involute line, high strength, large load bearing, easy to disassemble and assemble | ||||

| 螺纹元件 Threaded elements | W6Mo5Cr4V2高速工具钢。高温真空淬火热处理,60-62 W6Mo5Cr4V2 High speed tool steel. High temperature vacuum heat treatment, 60-62 | ||||

| 料筒 Drum | 1套 1 set | ||||

| |||||

| 长度 Length | 290mm/节,共12节筒体 290mm/j, a total of 12 sections of cylinder | ||||

| 材质 Material quality | 45钢镶@101整体合金套 45 steel inlaid @101 integral alloy sleeve | ||||

| 加热方式 Heating method | 电加热 electrical heating | ||||

| 冷却方式 Cooling-down method | 水冷却 water cooling | ||||

| 串联方式 Serial mode | 第1节筒体为4D喂料筒体,第5.8.11节筒体为抽真空筒体,第13节筒体为挤出筒体,其余筒体为闭口筒体 Section 1 is a 4D feeding cylinder, section 5.8.11 is a vacuum cylinder, section 13 is an extrusion cylinder, and the rest are closed cylinders | ||||

| 机筒加热方式 Barrel heating method | |||||

| 控温段 Temperature control section | 料筒段 The barrel section | 加热片型式 Heating plate type | |||

| 进料区 Feed zone | 第一段 Paragraph 1 | 不加热 No heating | |||

| 一区 Zone 1 | 第二段 Paragraph 2 | 红外线加热器 infrared heater | |||

| 二区 Zone 2 | 第三段 Paragraph 3 | 红外线加热器 infrared heater | |||

| 三区 Zone 3 | 第四段 Paragraph 4 | 红外线加热器 infrared heater | |||

| 四区 Zone 4 | 第五段 Paragraph 5 | 红外线加热器 infrared heater | |||

| 五区 Zone 5 | 第六段 Paragraph 6 | 红外线加热器 infrared heater | |||

| 六区 Zone 6 | 第七段 Paragraph 7 | 红外线加热器 infrared heater | |||

| 七区 Zone 7 | 第八段 Paragraph 8 | 红外线加热器 infrared heater | |||

| 八区 Zone 8 | 第九段 Paragraph 9 | 红外线加热器 infrared heater | |||

| 九区 Zone 9 | 第十段 Paragraph 10 | 红外线加热器 infrared heater | |||

| 十区 Zone 10 | 第十一段 Paragraph 11 | 红外线加热器 infrared heater | |||

| 十一区 Zone 11 | 第十二段 Paragraph 12 | 红外线加热器 infrared heater | |||

| 十二区 Zone 12 | 第十三段 Paragraph 13 | 红外线加热器 infrared heater | |||

| 十三区 Zone 12 | 机头 handpiece | 铸铜加热器 Copper heating element | |||

| 2.2. 真空强制排气设备 Vacuum Forced Exhaust Equipment | |||||

| |||||

| 水环真空泵 Water ring vacuum pump | SK-5.5淄博联谊真空泵厂 SK-5.5 Zibo Lianyi vacuum pump factory | ||||

| 驱动电机 Drive motor | 5.5KW交流 5.5KW AC | ||||

| 最大吸气量: Maximal inspiratory capacity: | 87m³/h | ||||

| 工作液量 Working fluid volume | 0.8m³/h | ||||

| 真空管道处理 Vacuum pipe treatment | 镀铬 chromate treatment | ||||

| 2.3. 软水设备 Soft Water Equipment | |||||

| |||||

| 机筒内采用软水冷却,软水箱与机体分离,便于清洗和维修。 The barrel is cooled by soft water, and the soft water tank is separated from the body for easy cleaning and maintenance | |||||

| 冷却形式: Cooling form: | 水冷 Hydrocooling | ||||

| 冷却泵 Cooling pump | 1.1KW | ||||

| 电磁阀 Electromagnetic valve | 意大利进口 Imports from Italy | ||||

| 水管处理 Water treatment | 紫铜镀铬 Purple copper plating chromium | ||||

| 2.4. 液压换网设备 Hydraulic Mesh Equipment | |||||

| |||||

| 换网设备 Network Switching Unit | 功率1.5KW,多孔板直径65,热切模板17*Φ4.5 Power 1.5KW, porous plate diameter 65, hot cutting template 17*Φ4.5 | ||||

| 2.5. 输送带 Conveyor belt | |||||

| |||||

| 不锈钢材质,电机功率,宽度400MM,另加24米输送带,每米带风扇 Stainless steel material, motor power, width 400MM, plus 24 meters conveyor belt, each meter fan | |||||

| 功率 Power | 0.37KW | ||||

| 电机功率 Motor power | 4KW | ||||

| 龙门500型切粒 Longmen 500 type pellet cutting | 切粒功率7.5KW,英威腾变频调速。 Chipping power is 7.5KW, and the frequency converter speed control is implemented by Invtex. | ||||

| 2.6. 电气控制柜 Electric control cabinet | |||||

| |||||

| 油润滑设备与主机联锁 The oil lubrication system is interlocked with the main engine | 启动油泵后,才能启动主机 The main engine can only be started after the oil pump is started | ||||

| 喂料设备与主机联锁 The feeding system is interlocked with the main engine | 启动主机后,才能启动喂料机 The feeder can only be started after the host is started | ||||

| 压力设备与主机联锁 The pressure system is interlocked with the main engine | 过压时,主机及喂料均停止工作 In overvoltage, the main engine and feeding stop working | ||||

| 电流与主机联锁 The current is interlocked with the main engine | 过电流时,主机及喂料均停止工作 When the current is too high, the main engine and feeding stop working | ||||

| 电压Voltage | 3X380V,交流50Hz / 3X380V, AC 50Hz | ||||

| 双螺杆主电机 Double screw main motor | 交流电机,160KW西门子贝得电机,尾部独立风扇 Alternating current motor, 160KW Siemens Bethe motor, independent fan at the rear | ||||

| 变频调速 frequency control | 英威腾变频调速 Invt frequency conversion speed | ||||

| 主要电器 Major electrical appliances | 法国施耐德与正泰公司产品 Products of Schneider and Chint in France | ||||

| 温控仪表 Temperature control instrument | 日本欧姆龙公司智能型温控仪表 Japan Omron intelligent temperature control instrument | ||||

| 压力传感器 pressure pickup | 0~50Mpa | ||||

| 电磁阀 electromagnetic valve | 荷兰乔克电磁阀 Dutch Jock solenoid valve | ||||

| 加热控制 heating control | 温控表通过固态继电器控制,采用耐高温导线 The temperature control table is controlled by solid state relay and uses high temperature resistant wire | ||||

| 电器控制柜控制 Control by electrical control cabinet | 温控设备;驱动设备;联锁联控设备,带独立可移动操作柜,方便工人师傅操作设备运行 Temperature control system; drive system; interlock and control system, with independent mobile operation cabinet, convenient for workers to operate the equipment | ||||

| 2.7. 随机备品备件资料 Random spare parts data | |||||

| 螺纹元件Threaded elements | 300mm | ||||

| 齿轮箱输入油封 Gear box input oil seal | 1套 1 set | ||||

| 齿轮箱输出油封 Gear box output oil seal | 1套 1 set | ||||

| “O”型圈 “O” molding ring | 6件 Six | ||||

| 尼龙销 Nylon pins | 1套 1 set | ||||

| 热电偶 thermocouple | 2件 2 copies | ||||

| 固态继电器 solid state relay | 2件 2 copies | ||||

| 电磁阀 electromagnetic valve | 1件 electromagnetic valve | ||||

| 工具箱hold-all | 1套1 set | ||||

| 技术文件: 电器安装图纸一套,双螺杆挤出机说明书一本,变频器说明书一本,温控表说明书一本,及螺杆组合图一份。 Technical document: A set of electrical installation drawings, a manual for twin-screw extruder, a manual for frequency converter, a manual for temperature control meter, and a screw combination diagram. | |||||

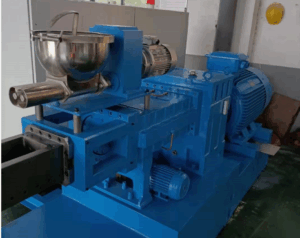

- 切粒机

Dicing Cutter Machine

| 电源要求 Power Supply | 380V/3P/50Hz |

| 功率 Power | 8Kw |

| 设备尺寸(长 × 宽 × 高)Dimension of the Equipment (Length x Width x Height) | 1000mm*800mm*1500mm |

| 总重 量 Weight | 0.9Ton |

| 设备挤出产量 Capacity | 650kg/h. |

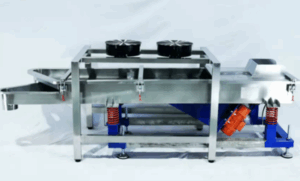

- 振动筛设备

Oscillating Screen Equipment

| |

| 电源要求 Power Supply | 380V/3P/50Hz |

| 功率 Power | 0.5Kw |

| 设备尺寸(长 × 宽 × 高)Dimension of the Equipment (Length x Width x Height) | 2500mm*700mm*700mm |

| 总重 量 Weight | 200kg |

| 设备挤出产量 Capacity | 650Kg/h |

| 振动筛 Oscillating screen | 不锈钢材质,宽度700mm,长2.5米 Stainless steel material, width 700mm, length 2.5m |

Reviews

There are no reviews yet.