- Home

- Uncategorized

- 130 PP EXTRUDING MACHINE

130 PP EXTRUDING MACHINE

Technical configuration

( Single-screw high-transparency cup-making thermoforming sheet machine unit)

| 一.General information | |

| Power supply | 380V 50HZ; 3phase 4 wire |

| Applicable material | PP particles, crushing materials |

| Sheet width Max. Sheet thickness | 700-800mm 0.22-2.6 |

| Sheet Application | Thermoforming sheet for cup |

| Max. Capacity PP130 | 800kg /h |

| Designed line speed | 3.5-35M / Min |

| Main power | About 190KW |

| Compressed air | 2M3 / h, 0.5—0.7Mpa |

| Cooling water | 6M3 / h; 25℃ |

| Noise stand | <75dB |

| 二.Main equipment composition | |

| DN-MC2/1-UPGRADE |

| DN-MC2/2-UPGRADE |

| DN-MC2/3-UPGRADE |

| DN-MC2-UPGRADE |

| DN-MC2/4-UPGRADE |

| DN-MC2/5-UPGRADE |

| DN-MC2/6-UPGRADE |

| DN-MC2/7-UPGRADE |

Category: Uncategorized Tag: DN-MC2-UPGRADE

- Description

- Reviews (0)

Description

Description

Model: DN-MC2-UPGRADE

Detailed specifications and configuration of equipment and components

- Sheet carrier: DN-MC2/1-UPGRADE

| Edge material winding machine | |

| Power | Using torque motor, installed on the transition frame |

| Edge cutter | |

| No power | Round hob |

| Number of workstations | 2 station |

| mechanical knife | 1 set |

| Power | Using torque motor, installed on the transition frame |

| Wind knife Device | |

| Cooling bracket, trimming assembly | |

| Length | 7 m |

| Transition roller | 80 aluminum roller, surface anodized, polished, no locking phenomenon |

| Trimming components | It adopts the form of upper and lower hobs and is installed on the transition frame. |

- Feeding Equipment (large bin + hopper): DN-MC2/2-UPGRADE

| Spiral feeding, hot air mixer | One each |

| Stock bin | 1set |

- Three roller calender: DN-MC2/3-UPGRADE

| Three roller calender | |

| Calender form | L form |

| Roller diameter | Front roller Φ370, middle rear roller Φ550mm, coaxiality ≤0.005mm, circular diameter ≤0.005mm, |

| Roller length | 1000mm |

| Roller material | 42rom alloy steel forged parts |

| Roller surface finish | Super mirror finish,Ra≤0.015um |

| Roller surface hardness | HRC58-62 |

| Chrome plating thickness | 0.08-0.12mm |

| Rack | The weldment is connected and tempered |

| Move motor power back and forth | 0.75kw, can move forward and backward (electric) |

| Roller drive | Three independent reduction motor drives |

| Five roller reduction box | Forno |

| Five roller drive power | Inovance servo 4.4KW, three units |

| Frequency Control | Inovance servo speed regulator |

| Roller opening and closing | Electric screw lift |

| Roller gap adjustment method | It adopts worm gear pitch adjustment, with dial indicator device, with instant stop switch, and synchronous control system. |

| Three rollers adopt bearings | Japan NSK |

| Five roller drive power | Inovance servo 4.4KW, three units |

| Frequency Control | Inovance servo speed regulator |

| Roller opening and closing | Electric screw lift |

| Roller gap adjustment method | It adopts worm gear pitch adjustment, with dial indicator device, with instant stop switch, and synchronous control system. |

| Three rollers adopt bearings | Japan NSK |

| Roller structure | Single head water inlet and outlet type |

| Type | Split type (with water tank) |

| Cooling medium | Water (soft water is best) |

| Temperature control | Accuracy ≤±1℃, with automatic overpressure, overtemperature, pump failure alarm and other functions |

| Rotary joint | It adopts the inner tube rotating multiple flow type, and the water pipe connected to the three rollers adopts a steel wire rubber double-layer pipe, which is resistant to high temperature and high pressure. |

| Water pump power | 3 sets of 3.75kw pressure pumps |

| Heating | 9KW/group, using increased size switch |

| Water tank | Made of stainless steel, all pipes are 1.9685 inches |

| Water valve | 1″ Pneumatic Angle Seat Valve |

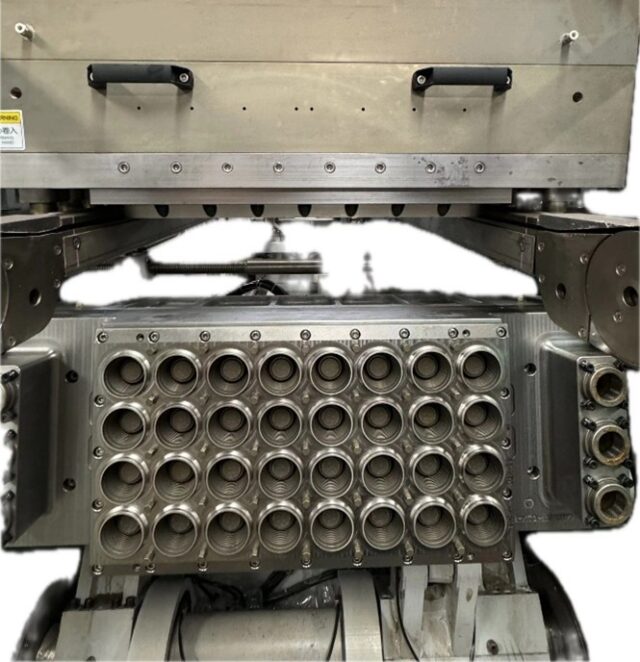

- Host machine: 130 Polypropylene Extrusion (DN-MC2-UPGRADE)

| YRφ130/36 Single screw extruder | |

| Barrel screw | High quality alloy steel 38CrMoAlA, |

| Nitriding depth | 0.5mm-0.7mm |

| Screw hardness | ≥960HV |

| Barrel hardness | ≥1100HV |

| Screw diameter | ø130mm |

| Aspect ratio | 36:1 |

| Screw speed | 90cycles/min |

| Number of barrel heating zones | 9 |

| Total heating power | About 70KW |

| Heating method | Ceramic heating ring/stainless steel insulation cover |

| Cooling method | Double cylinder fan cooling |

| Fan power | 370W/set |

| Motor | AC variable frequency motor |

| Brand | Siemens Bader |

| Motor Power | 160kw |

| Motor speed | 1500rpm |

| Speed governor | Siemens frequency converter |

| Reduction gearbox | It adopts hard tooth surface cylindrical gear reduction box. The gear is made of high-strength low-carbon alloy steel through carburization and fire treatment. The tooth surface hardness reaches HRC58-62. |

| Motor and reduction gearbox connection method | Direct connection, coupling connection |

| Double column screen changer | |

| Screen changer specifications | ø 170MM double column single hole |

| Equipped with hydraulic station | Maximum pressure 16MPa |

| Metering pumps | |

| Specifications (guaranteed no traces of metering pump gear) | 200CC |

| Driving power | 11KW |

| Frequency Control | Siemens |

| Metering pump revolutions | 90cycles/min |

| Metering pump and reduction gearbox connection | Using universal coupling |

| Mold (Zhejiang Jingcheng) | |

| Mold effective width | 950mm |

| Die lip adjustment method | The upper die lip is fixed, and the lower die lip is adjusted by a push-type mechanical device; the width of the outer baffle is adjusted, the length of the baffle is 300mm, and both sides need to be heated. |

| Number of heating zones in the die head | 5 |

| Die material | 5CRNIMO |

| Heating power | About 20KW |

| Mold structure | Hanger type |

| Mold cavity treatment | Surface chrome plating and polishing treatment, the thickness of the coating after polishing is greater than 0.06MM, and the surface finish is ▽12 or above |

- Blender mixer (DN-MC2/4-UPGRADE)

| Power | 20KW |

| Voltage | 380V/50Hz/20KW |

- Water roller temperature controller (DN-MC2/5-UPGRADE)

| Power | 10kw |

| Voltage | 380V/50Hz/20KW |

| Dimension | 1800*1200*2250mm |

- Electric cabinet (DN-MC2/6-UPGRADE)

| Electric control cabinet form | Standing cabinet type | |

| Control Panel | Touch screen, PLC control. | |

- Winding machine (DN-MC2/7-UPGRADE)

| Rewinding diameter | 1500-2000mm |

| Rewind reel diameter | Φ76x 1000mm |

| mobile car | 4 units |

| Power unit | Inovance servo motor |

| Number of winding stations | 3 Stations |

| control unit | Length counter signal control |

| Meter counter | Korea Autonics, mounted on the traction roller |

Random spare parts list

| Bolt wrenches, screwdrivers and other tools | 1set |

| Screw removal device | 1set |

| Thermocouple | 2pieces |

| Solid state relay | 2pieces |

| copper feeler gauge | 1set |

| Mold tool box | 1set |

| water temperature control heating rod | 1 stick |

| Mold heating rod | 2sticks |

| Screen changer heating rod | 2sticks |

| Metering pump heating rod | 2sticks |

Electrical components

| Barrel screw | Yingrun |

| Host gearbox | Dongli gearbox factory |

| Host motor | Siemens Bader |

| roller | Yingrun |

| air switch | Chint |

| Mold | Zhejiang Jingcheng |

| Contactor. Knob. Buttons etc. | Siemens |

| Frequency converter | Siemens |

| PLC system | Siemens |

| Winding motor | Inovance servo |

| Barrel screw | Yingrun |

Others

| Equipment appearance color | Can be customized |

| Production line arrangement direction | Left handpiece (the operating surface is on the left along the extrusion direction) |

| Cable and pipe installation methods | The purchaser digs the trench and installs it in the trench. The dimensions and length of the trench are shown in the drawings provided by the supplier. |

| Technical documents provided | Instructions and maintenance books for major electrical appliances and parts, as well as equipment water, electricity, gas and equipment installation diagrams |

Excluded parts (need to be provided by the ordering party)

- Forklifts, cranes, etc. required for loading, unloading and positioning the equipment into the buyer’s factory

- Water, electricity, gas and oil required for equipment

- Cables to the equipment control cabinet, roller temperature controller, and drying system

- Installation components required for wall work and special layouts

- Pipe support

- Other items not listed in this contract

Reviews (0)

Be the first to review “130 PP EXTRUDING MACHINE” Cancel reply

Reviews

There are no reviews yet.