- Home

- Uncategorized

- FULLY AUTOMATIC PACKING MACHINE

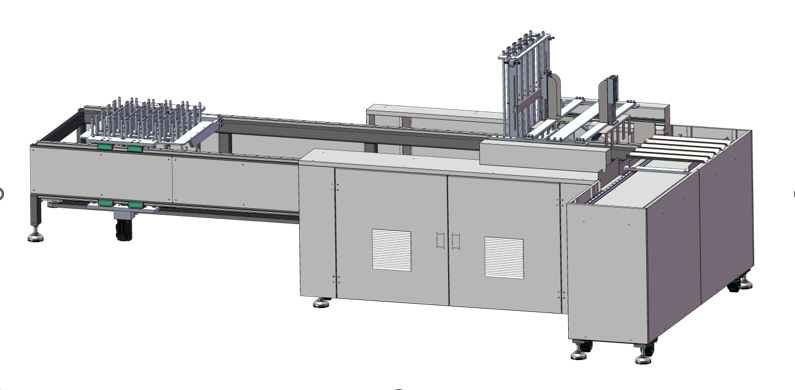

FULLY AUTOMATIC PACKING MACHINE

- The system includes: two sets of mobile material receiving frames, flipping frames, lifting mechanisms, pushing mechanisms, horizontal conveying mechanisms, and packaging machines;

- Working principle: The multi station top cutting mechanism counts and stacks the products on the sheet down into a set of mobile material receiving frames. When the counting stack reaches the set quantity, the mobile material receiving frame quickly moves to the bottom of the flipping frame. At this time, the other set of mobile material receiving frames quickly reaches the material receiving position. The lifting mechanism stacks the flipping frames up to form a row, and the flipping frames flip 90 degrees. The pushing mechanism pushes them onto the horizontal conveying mechanism, and the horizontal step-by-step conveying sends a single product into the counting and packaging machine, and the packaging is completed;

- Applicable products: cup lid

- Applicable size: ≤φ 160mm;

- Replacing products is convenient and fast, just replace: two sets of mobile material receiving frames, flipping frames, lifting rods, material support plates, and horizontal moving trays.

Category: Uncategorized

- Description

- Reviews (0)

Description

Description

- Two sets of mobile material receiving frames: each set is processed and assembled from aluminum alloy material, and the horizontal movement is driven by a planetary reducer (brand: Zhongda) equipped with a 0.75kW servo motor (brand: Inovance), which is driven by synchronous wheels and synchronous belts; Vertical lifting is driven by a 0.75kW servo motor (brand: Inovance) and a ball screw (brand: Fulei)

- The flip frame is processed and assembled from aluminum alloy material, and the 90 ° flip is driven by a cylinder (brand: AirTAC);

- The lifting mechanism is processed and assembled from aluminum alloy material, and the lifting is driven by a rodless cylinder (brand: AirTAC)

- The pushing mechanism consists of a cylinder (brand: AirTAC) and a guiding mechanism;

- The horizontal conveying mechanism adopts a planetary reducer (brand: Zhongda) equipped with a 0.75kW servo motor (brand: Inovance), which is driven by synchronous wheels and synchronous belts; When two packaging machines are required, the horizontal conveying mechanism uses two sets of power and two horizontal moving trays;

- Electrical part: Controlled by Inovance PLC, handheld human-machine interface adopts Inovance touch screen

- Equipped with a three sided sealing packaging machine, when one packaging machine cannot meet the factory’s capacity, two packaging machines can be optionally equipped.

- Equipment dimensions: 5180mm * 2100mm * 1500mm

- Equipment weight: 1.5 tons

- Equipment power: 3750W

- Power supply: Three-phase four-wire 380V, 50Hz

Reviews (0)

Be the first to review “FULLY AUTOMATIC PACKING MACHINE” Cancel reply

Reviews

There are no reviews yet.